Extend Coolant Life, Improve Finish Quality, and Reduce Maintenance Downtime

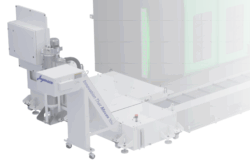

Jorgensen provides chip conveyor and filtration solutions for all types of CNC machine tools, from small lathes and machining centers to large gantry mills. Whether you need a solution for a single machine or a central system, we deliver reliable, application-specific chip removal and coolant filtration. Machine tool systems are available as either fully integrated solutions, stand alone, or engineered to order.

✓ Keep coolant clean and machines running smoothly

✓ Efficiently remove chips and reduce coolant waste

✓ Improve recycling value

✓ Enable lights-out automation

✓ Improve manufacturing productivity

Reliable Craftsmanship

Jorgensen conveyor and Filtration systems are manufactured to the highest quality standards following ISO 9001:2015 standards. Our durable construction is known to last decades in the field.

X-treme duty enhancements are available for challenging environments. We pride ourselves in providing customers with the best-fitting conveyor for long-term success.

Professional Support for Your Machining Needs

Our engineers assess your manufacturing process to match you with the most effective chip and coolant system. We consider your cutting process, chip type and volume, coolant flow, and space constraints to recommend the most efficient system for your CNC machine tool.

Case Studies & Resources

- Jorgensen for Dealers and Resellers

- Filtering a New Channel to Productivity: High-volume, High-mix Swiss Turning

- Streamlined Filtration Keeps Aerospace Composite Cutting Clean

- Jorgensen MunchMan® Conveyors Reduce Hazardous Coolant Waste Removal by 75%

- Giant Magellan Telescope Project

- Choosing the Right System for Maintenance-Free Machining