Cooling

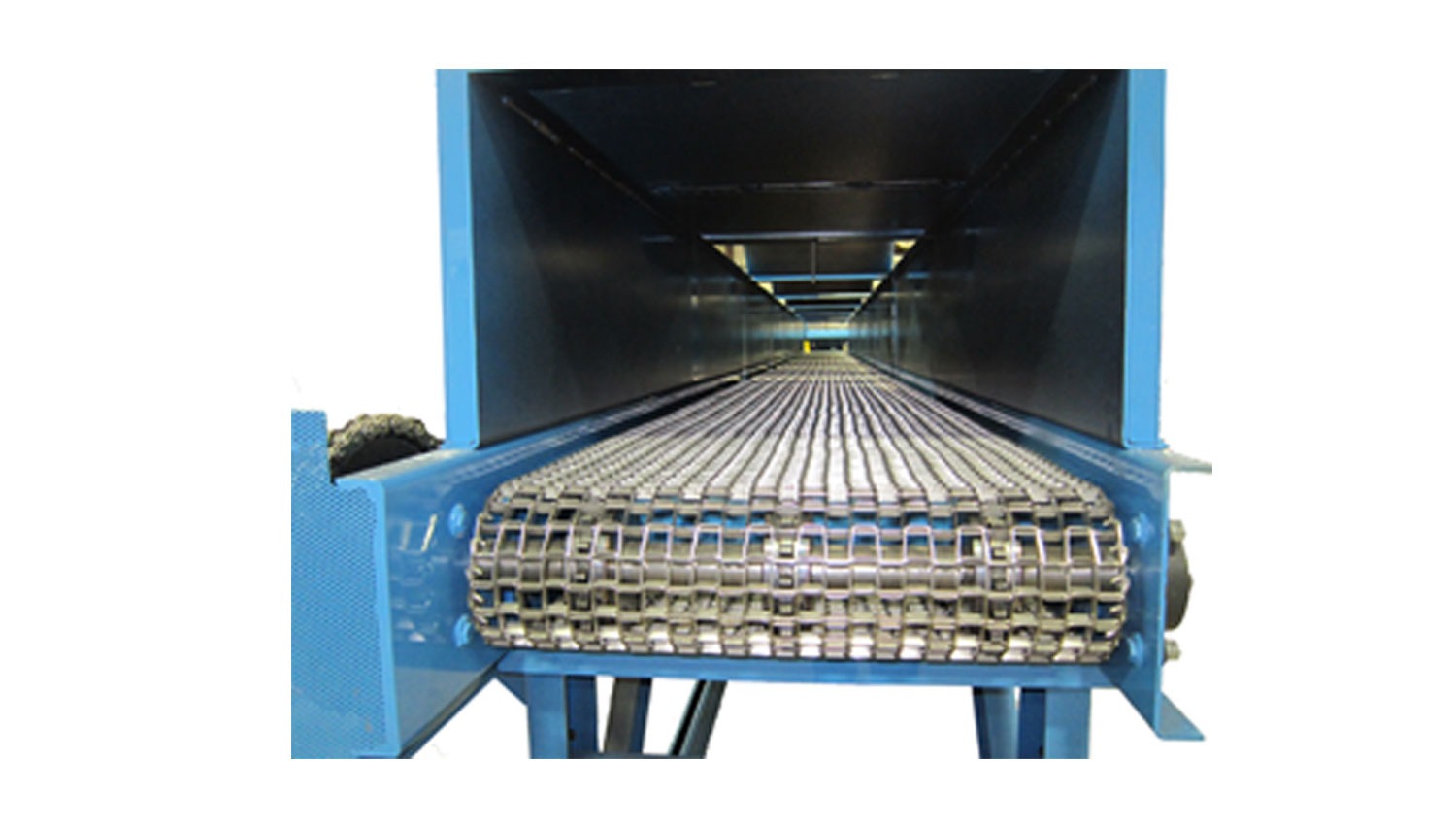

Jorgensen offers a complete line of engineered conveyor solutions for your metal parts cooling application. For industrial cooling of metal parts, it is crucial to choose conveyors that can handle the weight and temperature of the parts while efficiently cooling them down. Metal parts can retain a significant amount of heat after manufacturing processes like casting, forging, or heat treatment. Perforated or meshed belts can be used to allow air circulation for faster cooling. Belt conveyors are suitable for medium to heavy-duty cooling applications. Drag chain, slat and wire mesh conveyors can handle heavy loads and are well-suited for cooling metal parts that are robust and not prone to damage. They offer a reliable and robust cooling solution for large, small, light and heavy metal parts.

We incorporate various types of fans, chillers, air knives, quench tanks and sensor technologies to provide the precise control you need in your cooling application. Cooling tunnels are specially designed conveyors with insulated enclosures and controlled airflow for efficient cooling.

Our team will assist in the proper conveyor selection and design to ensure effective cooling and help maintain the quality of the metal parts during the cooling process. Additionally, safety considerations will be taken into account when handling hot metal parts to prevent accidents or injuries.

Contact us to learn how these and other Jorgensen product solutions are made for your application!