Quenching

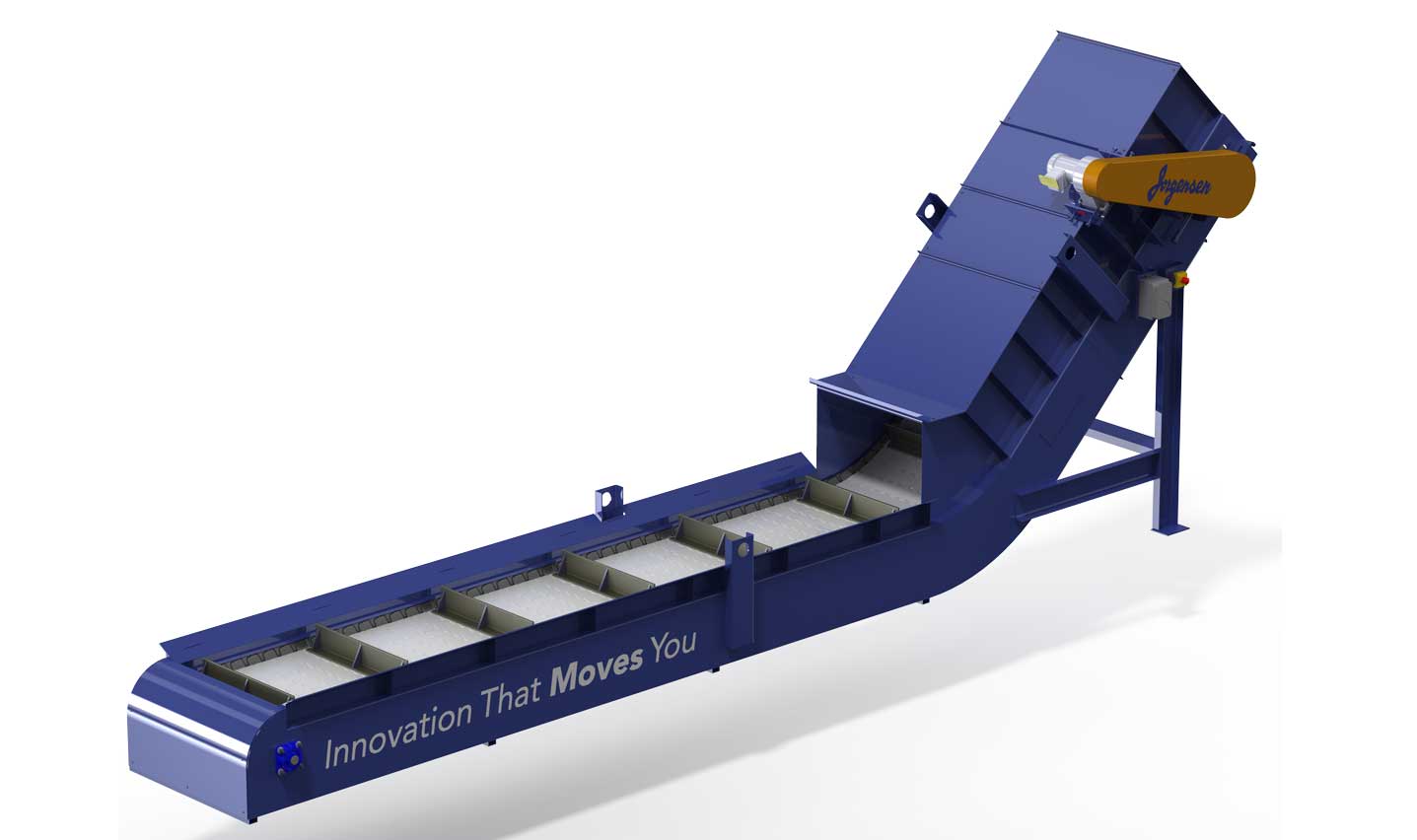

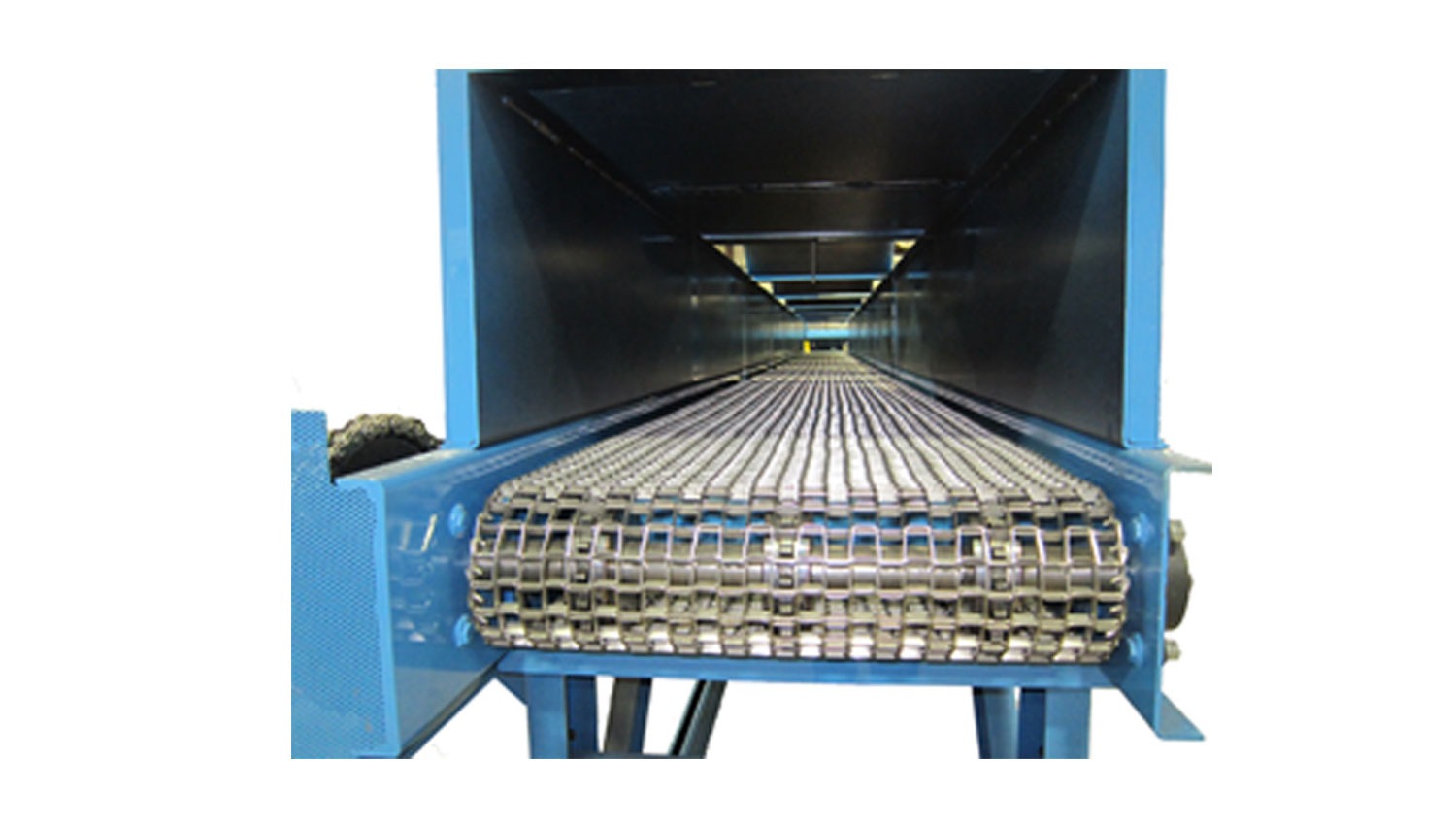

Jorgensen offers a complete line of quenching conveyors and tank solutions for quenching processes where extreme heat is employed in the manufacture of parts and where the material must be moved through a systematic “cool-down” process to ensure finished part integrity. Jorgensen can design and build quench tanks to integrate with the quenching conveyors, and the conveyors can be floor mounted, off-floor or pit mounted. Quenching conveyors can be designed with belts 3” wide to 90” wide and from a few feet long to hundreds of feet long. When selecting quench tank conveyor products for the quenching processes, factors such as the type of quenching media, the required cooling rate, workpiece sizes and weights, and the production volume should be considered. Properly designed and integrated conveyor systems in quenching processes ensure consistent and uniform cooling, resulting in hardened workpieces with the desired material properties. Additionally, safety features should be incorporated to protect operators from exposure to high-temperature quenching media.

We also offer our conveyors in several configurations – horizontal, horizontal set at an incline, horizontal transitioning to incline and horizontal with incline and returning to horizontal at the discharge point. Jorgensen also can design “pre-quench” conveyors with features to withstand the handling of high temperature parts and scrap, and we also can integrate cooling fans with these conveyors. Jorgensen has complete controls design and build capability for multiple conveyor system integration per our customer’s process requirements. We can design the full range of controls from simple relay logic to complex PLC – based controls.

Contact us to learn how these and other Jorgensen product solutions are made for your application!