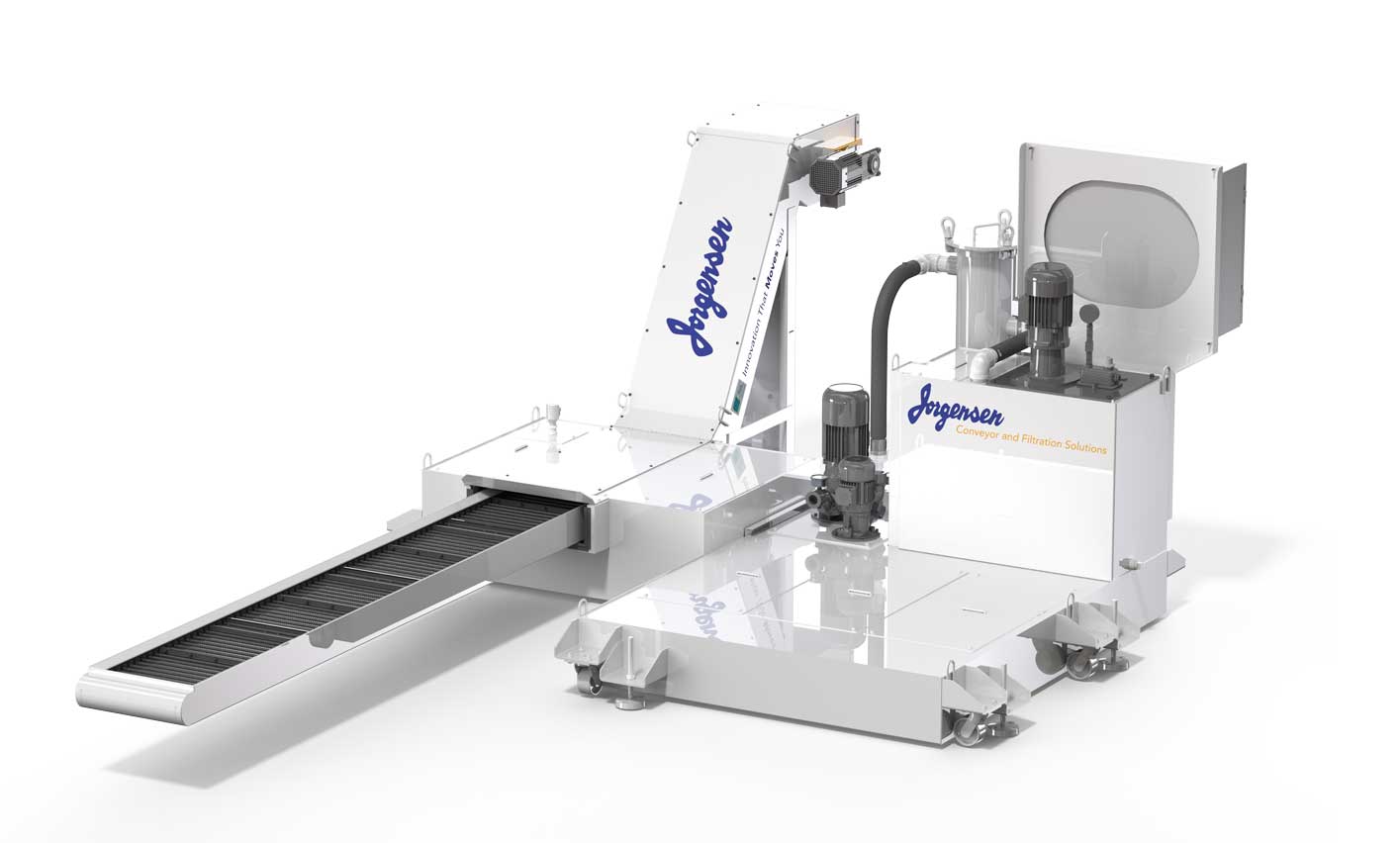

Integrated Conveyor/Filtration Solutions

Chip Removal and Coolant Filtration Systems

Complete CNC solutions combine chip removal and coolant filtration to create value from CNC machine tool wastes. Our engineers will work with you to create an integrated coolant tank with conveyor, to utilize the space available and reduce maintenance costs. Machine tool coolant systems utilize a wide variety of filter and conveyor types to maximize efficiency.

Conveyor types and options vary based on chip type, volume, and coolant flow rate. Filtration options vary based on coolant type and desired micron clarity. Options include cyclonic filtration, gravity media filtration, FlexForce high pressure systems, PermaClean, and more. All conveyor and filter products incorporate state of the art controls and sensors to optimize your custom coolant system’s performance.

Further incorporating chip processing components such as shredders, wringers, and briquetters increases recycling value and reduces costs associated with metal waste removal. Contact us for a custom quote.