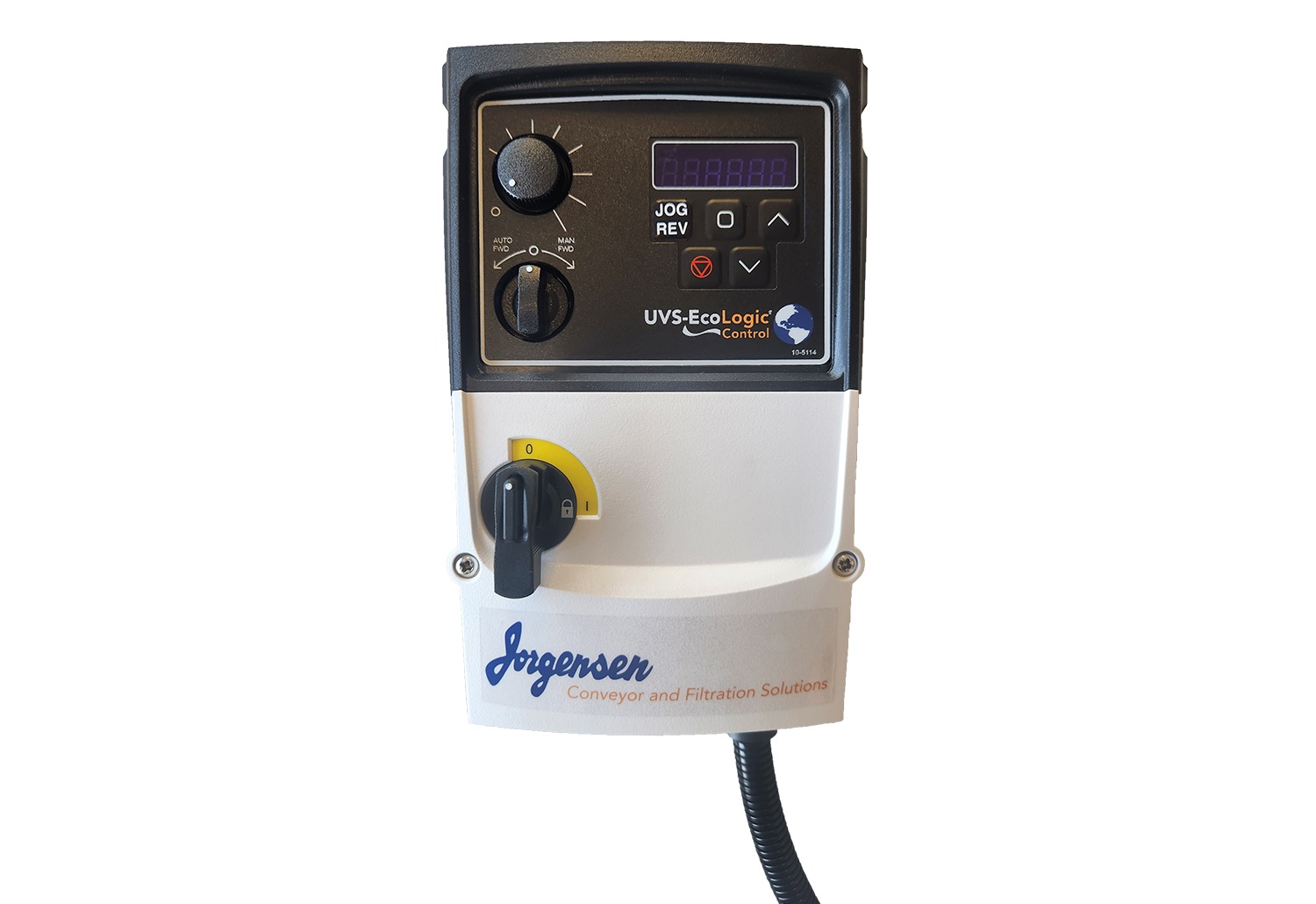

UVS EcoLogic® Control

Conveyor Controls for Maximizing Efficiency

The UVS EcoLogic® conveyor control provides maximum performance and efficiency for chip removal operations. Systems equipped with a UVS Ecologic Control save energy, decrease conveyor wear, and reduce coolant carryout. Conveyor control systems provide speed change, direction change, motor protection, external I/O & the patented Jam Manager® programming – all from a single unit.

The UVS serves as a complete conveyor control panel. Additionally, these can be used alongside custom controls unique to the user’s conveyor system needs.