Premium Briquette Press

Premium Briquette Press

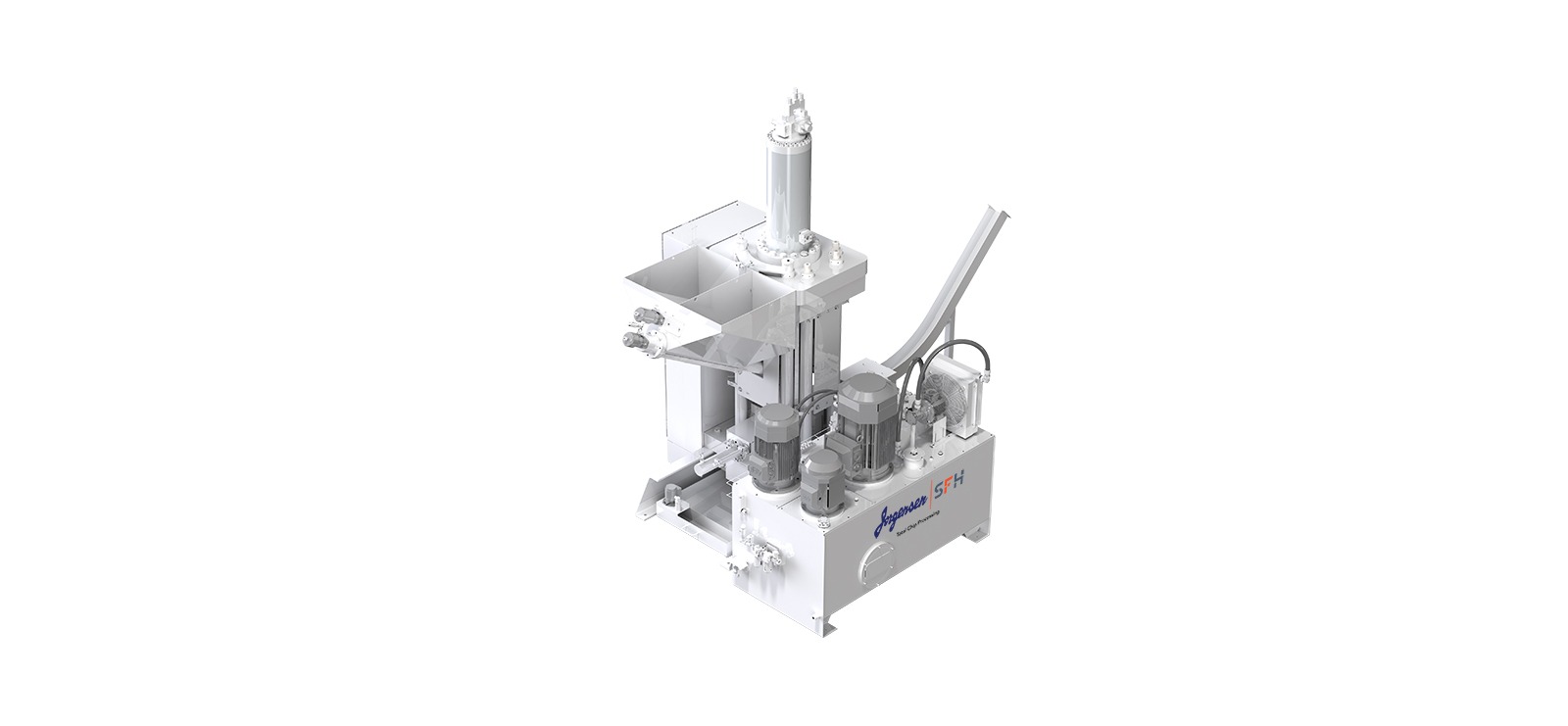

Hydraulic briquetters reduce chip volume and add value to machining waste while reclaiming cutting fluids.

The briquette machine uses hydraulic pressure to condense chips while pushing out residual cutting fluid. Volume reduction of scrap metal results in reduced disposal, transportation and storage costs. Metal briquettes can be used directly in re-smelting or sold to recyclers at an increased value versus loose chips.

A premium metal briquette machine is effective for a variety of materials including aluminum, titanium, copper, brass, steel and other metals. Additionally, this product can be combined with Jorgensen and SFH’s other chip processing equipment to provide a complete chip handling system.

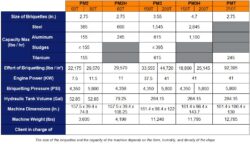

Jorgensen offers four premium metal briquette machine options to best fit the application needs. These models handle up to 1,100 lb/h of aluminum, 2,645 lb/h of steel. All models have a variety of options to choose from.