Forging

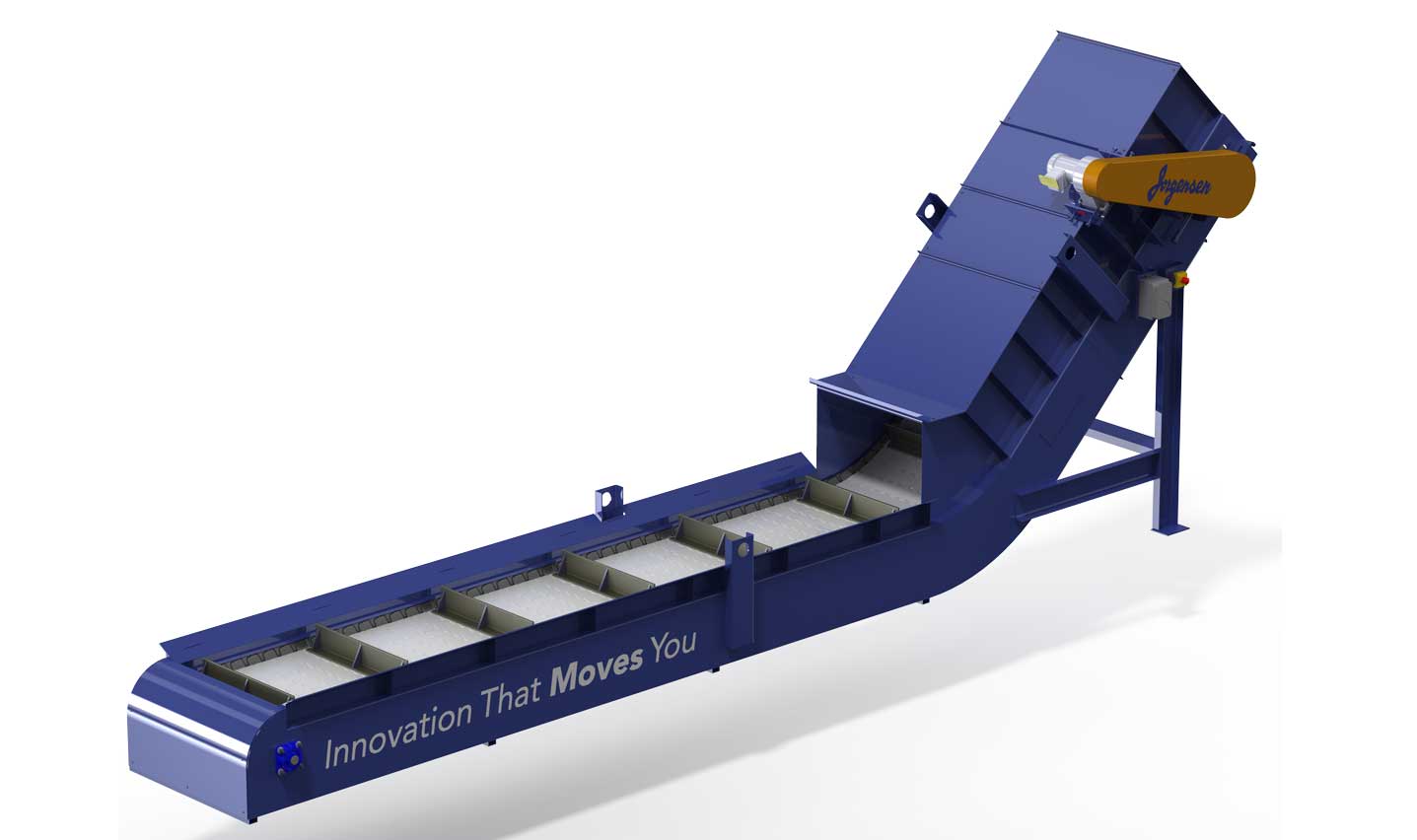

Jorgensen offers a complete line of engineered conveyor solutions for your forging application. Our conveyors are commonly used to transport workpieces through various stages of the forging process. The conveyors must be able to handle hot and heavy materials, as well as withstand the rugged and demanding conditions typically found in forging processes and the conveyor serves as a means of moving the workpieces efficiently and continuously from one workstation to another, allowing for a streamlined and automated production flow.

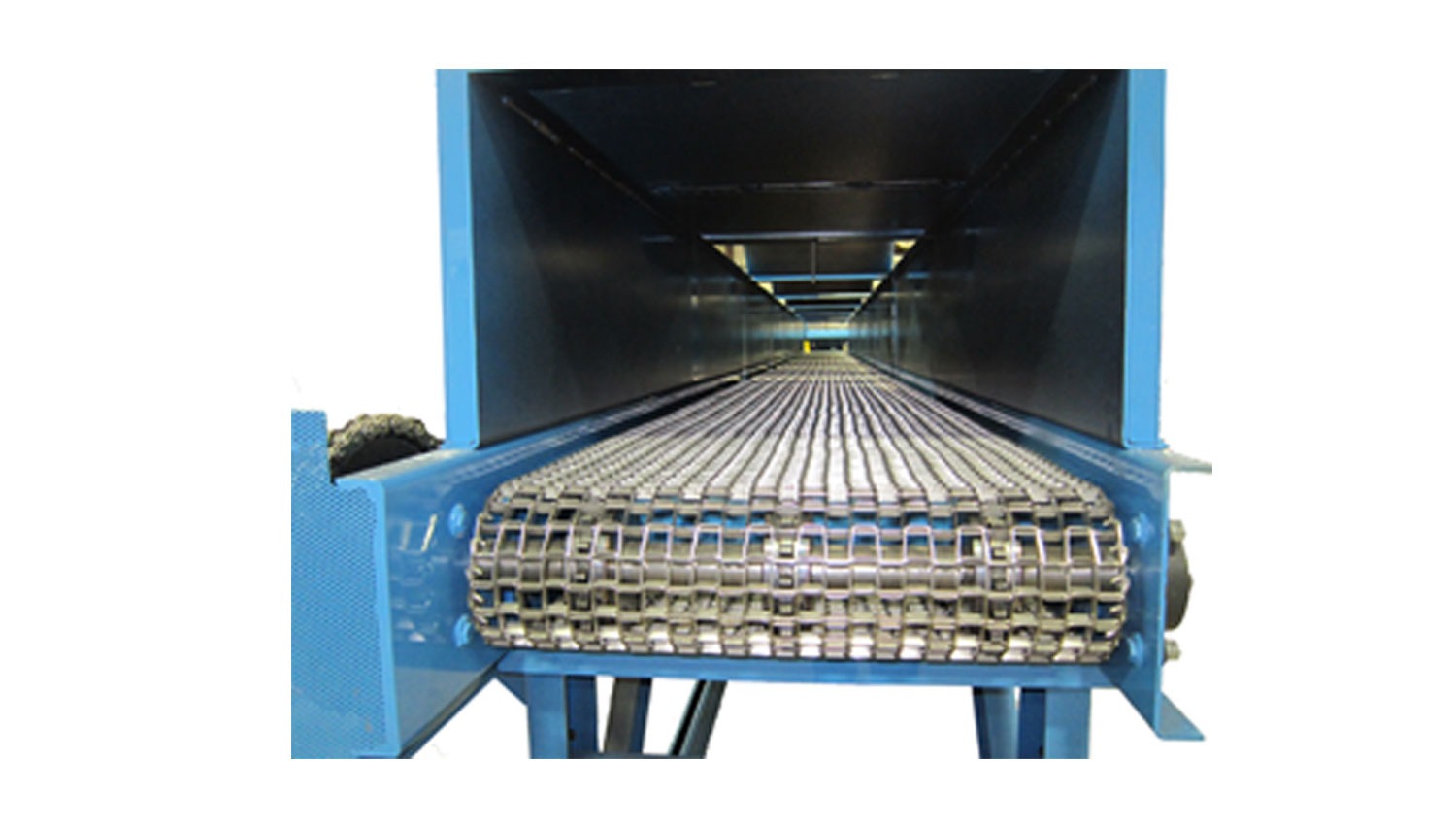

Our hinged steel belt conveyors are heat-resistant to withstand the high temperatures in the forging environment and are commonly used in forging applications for transporting and elevating metal products. Mesh belt conveyors can be best when transporting pieces at very high temperatures. Chain, slat or wire mesh conveyor belts will move individual pieces over long distances, both while hot or after cooling. When selecting conveyors for your forging applications, we will consider factors such as the weight and temperature of the workpieces, the layout of the forging facility, the required throughput, and any specific environmental conditions. It’s essential to choose conveyors that can handle the demands of the forging process, as well as ensure the safety of operators and the integrity of the forged products. Our sales engineering team will work with you to find the best solution for your specific application.

Contact us to learn how these and other Jorgensen product solutions are made for your application!