Extruding

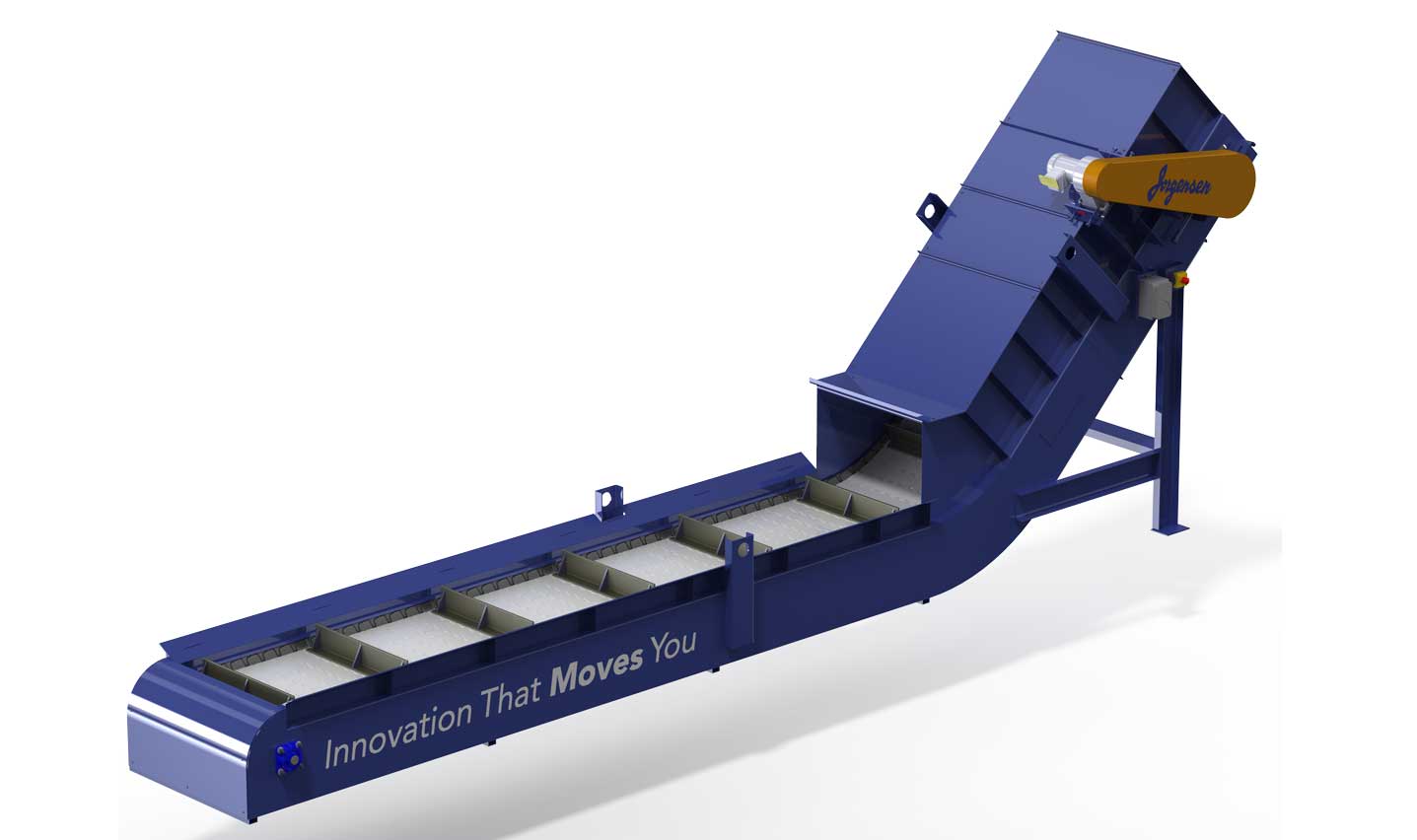

Jorgensen can design and build conveyors for your specific extrusion application. Whether it is a takeoff conveyor or a conveyor to handle your extrusion cutoffs, we have a solution for you.

Typically these conveyors can be designed using a wide variety of belt types that include, multi-ply rubber belt, engineered chain, flat top steel belt, hinged steel belt, wire mesh belt or rollers and can be designed for any length needed. These conveyors can handle a wide range of temperatures and can be designed to handle even delicate parts and extrusions. In most cases extrusion conveyors are horizontal in nature, but Jorgensen can design conveyors that elevate your material as well.

When selecting a conveyor for an extrusion application, factors such as the material type, temperature, production rate, layout, and required throughput should be considered to ensure the conveyor’s efficiency and suitability for the specific extrusion process. Additionally, safety measures must be implemented to prevent accidents and protect workers during material handling.

In addition, we can incorporate a wide variety of cooling technologies like air knives, fans and liquid baths. We employ a wide range of control technologies designed for your specific application that will ensure high productivity and precise control of your operation at a price that fits your budget.

Contact us to learn how these and other Jorgensen product solutions are made for your application!