Inspection

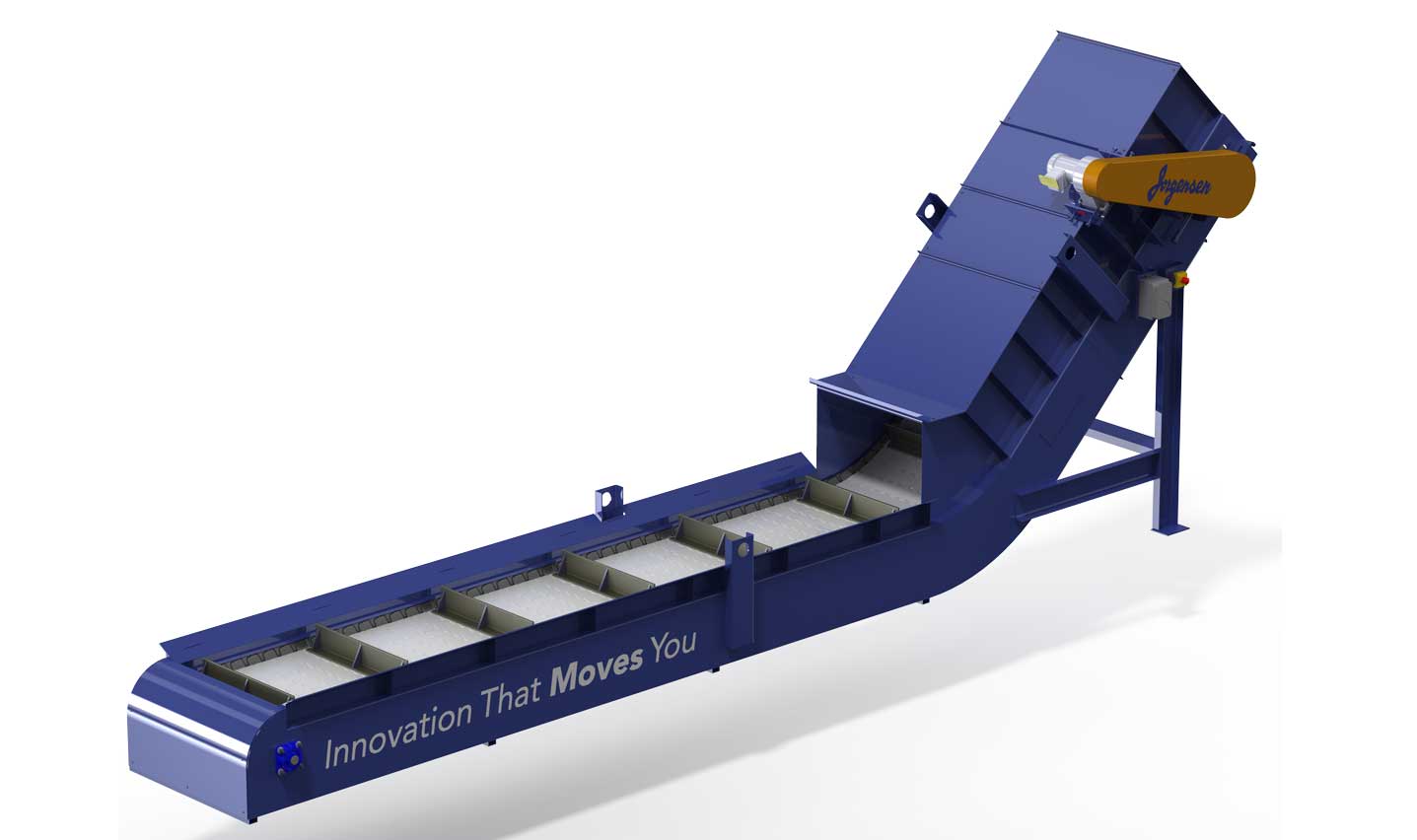

Jorgensen offers a complete line of engineered conveyor solutions for your parts inspection application. We offer a variety of belt surface materials: steel, chain, slat or slider bed and sizes ranging from 3” to 90” wide and lengths from a few feet to hundreds of feet. When designing a conveyor system for parts inspection, it’s essential to consider factors such as part size, weight, material, inspection criteria, and the desired inspection process. Integration with inspection devices, such as cameras, sensors, or automated inspection systems, is critical to ensuring accurate and efficient inspection. A well-designed conveyor system can enhance the accuracy and reliability of parts inspection, leading to improved quality control and increased productivity.

Whether the material to be handled is light or heavy, hot or cold, large or small, wet or dry, Jorgensen helps manufacturers achieve their ROI goals for lean and environmentally-friendly manufacturing with our ability to effectively work with you, provide SolidWorks drawings, and deliver with lead times to meet your production needs.

Contact us to learn how these and other Jorgensen product solutions are made for your application!