Plasma Cutting

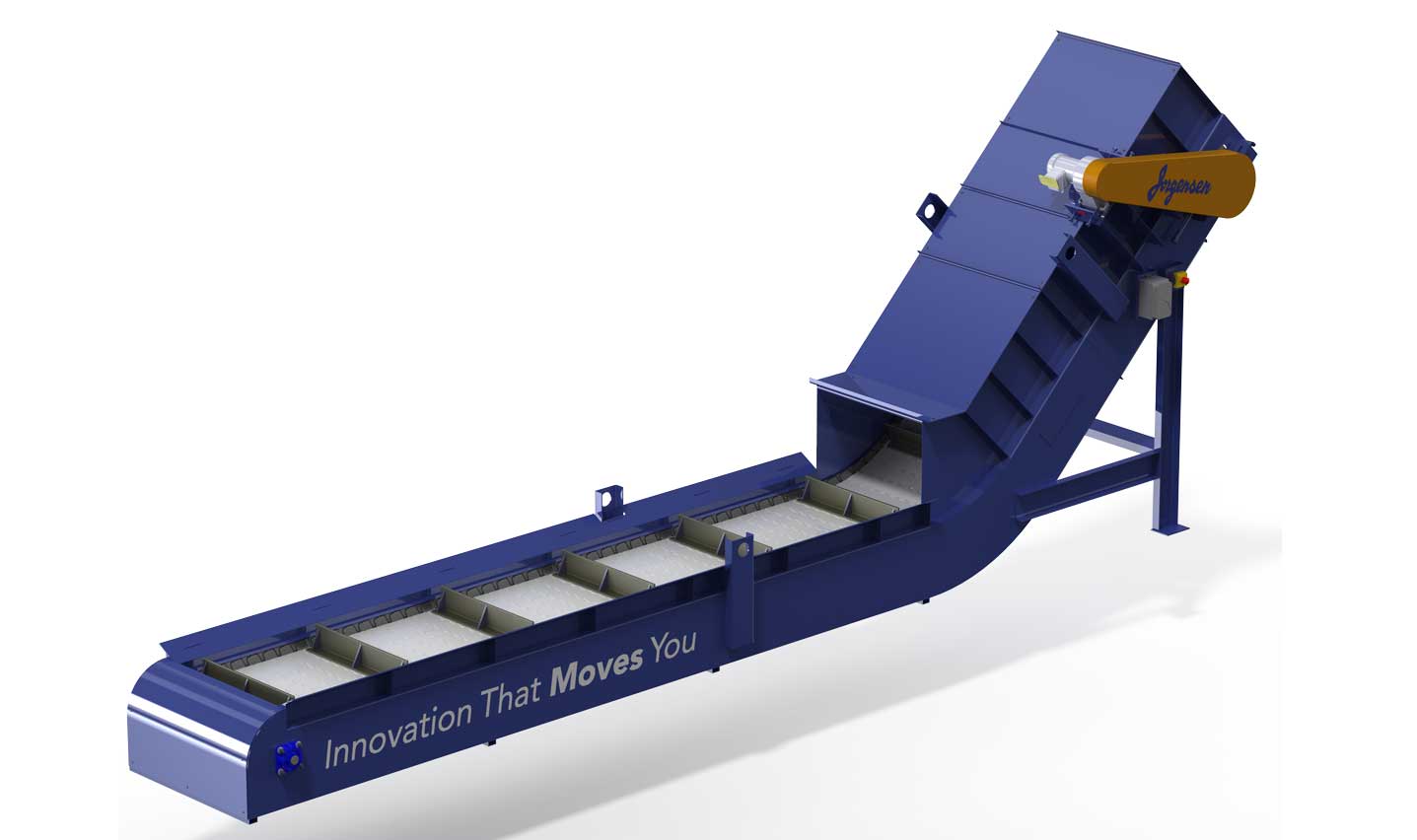

Jorgensen offers a complete line of engineered conveyor solutions for your plasma cutting application. These conveyors are often exposed to extreme environments that include high temperatures, abrasive materials and heavy scrap loads. They may be submerged in various types of quench tanks or in pits to capture plasma slag and scrap. Given the nature of the plasma cutting process we often incorporate abrasion resistant materials, impact bars and rails, heat bars and extreme duty conveyor casing and belt construction.

When selecting conveyor solutions for plasma cutting applications, factors such as the size and weight of the metal sheets or plates, the required throughput, the layout of the cutting area, and the level of automation needed should be considered. Properly designed and integrated conveyor systems in plasma cutting applications enhance productivity, reduce manual handling, and ensure precise material positioning, resulting in high-quality cutting outcomes. Safety features should also be implemented to prevent accidents and protect operators during the material handling process.

Plasma cutting systems that can vary greatly in size and shape, we will custom engineer a conveyor solution to meet your needs. Our conveyors can also be integrated into automated and semi-automated part removal systems and can incorporate various sensor and control technologies.

Contact us to learn how these and other Jorgensen product solutions are made for your application!