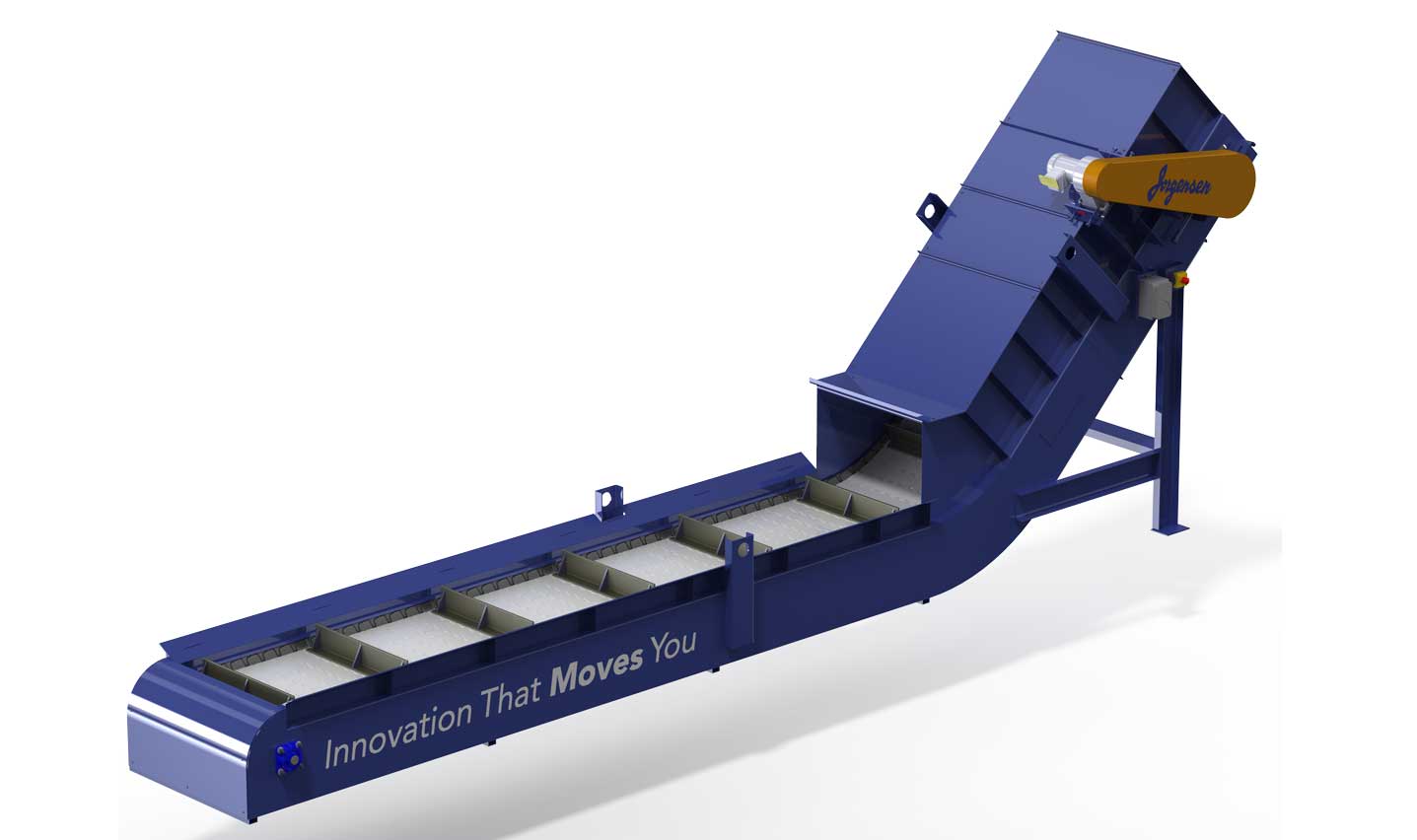

Hinged Steel Belt Conveyor 4” Pitch

Large, Hinged Steel Conveyors for Manufacturing

Large pitch conveyors effectively carry heavy, high-volume loads. A wide range of available dimensions makes these steel belt conveyors capable of moving material hundreds of feet. They are ideal for handling larger parts, stampings, scrap, metal chips, or turnings. 4″ pitch conveyors easily incorporate into larger systems to handle material wet or dry, in single or multiple unit systems. They excel in recycling, chip processing systems and metal manufacturing.